Powder Coating Troubleshooting Guide

Chapter Six: Pretreatment

Perhaps one of the most important steps in powder coating is pretreatment. Pretreatment allows for the proper adhesion of the powder to the substrate and ensures the long term adhesion of the coating to provide lasting resistance to corrosion. The process requires three steps:

Cleaning:

Removes soils, oils, oxides, smut, and contaminants

Factors to consider include accurate levels to improve soil removal, decrease the cleaning time and provide an optimum surface for the phosphate layer. Titration readings measure the total alkalinity or acidity levels. Increased temperatures will improve the action of the detergent and allow for less time in the cleaning process. Be careful to watch for sludge or soil build up in tanks that will reduce the cleaning activity even with good titration readings.

Rinse:

Removes any remaining contaminated solutions from the surface while diluting the chemicals to stop their action.

It also adjusts the pH for the next step.

Chemical Conversion of the Surface:

Common Types Include:

- Iron Phosphate for Ferrous Metals

- Zinc Phosphate for Ferrous Metals

- Chromate Conversion for Aluminum

- Manganese Phosphate

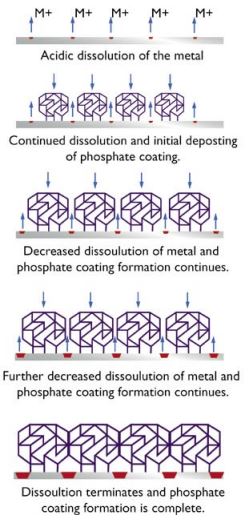

Conversion coatings are a complete film which changes the physical and chemical nature of the metal surface. These coatings deposition weights are measured in milligrams and are grey to blue iridescence or blue to gold iridescence. A clean surface is required for the reaction.

Seal

Neutralizer stabilizes the conversion coating.

The temperature of the rinse increases the solubility of the residues and improves dryoff time. Proper flow patterns and rinse volume promote a more thorough rinse. Overflows and screens are used for the removal of the soils, oils, and other contaminants.

Remember to WATCH:

- Water

- Action

- Time

- Chemicals

- Heat

|

Phosphate Comparisons |

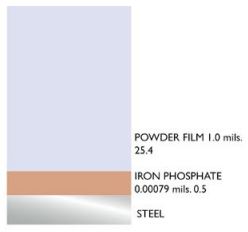

Cross Section of Phosphated and Coated Steel |

||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

Phosphate Control Factors |

Mechanism of Phosphating |

||||||||||||||||||||||

|

|

Other Chapters

- Early Powder Coatings, Uses, and Types

- Manufacturing of Powder Coatings

- Powder Chemistries, Formulations, Comparisons, and Uses

- Comparisons to Liquid Coatings

- Measuring Up the Product

- Powder Application Methods and Equipment

- Powder Coating Recovery Equipment

- The Electrostatic Charge Process

- Powder Application Tips

- Powder Curing Process

- Safety Issues With Powder Coatings

- TCI Troubleshooting Guide

- Glossary of Industry Related Terms